Home Surface Finish

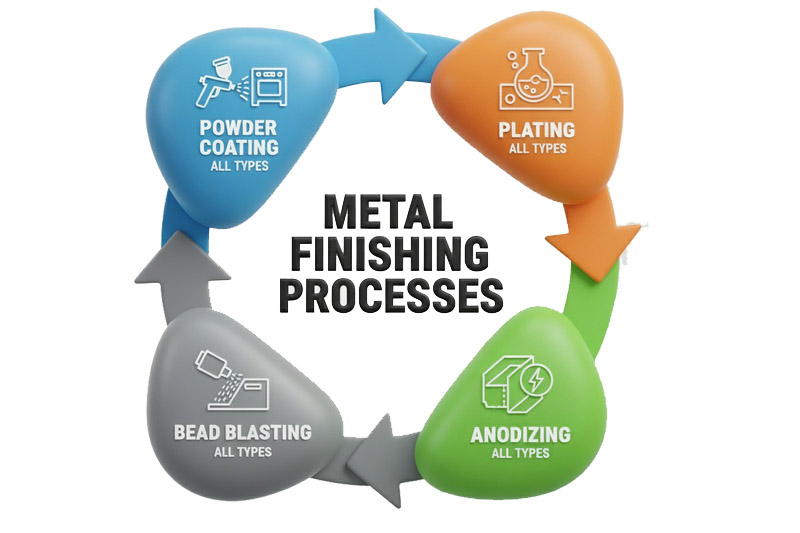

A secondary finish is an additional process applied to a metal part after its initial manufacturing and primary finishing. Think of it as the final touch. While the primary process might be casting or machining to get the basic shape, the secondary finish is all about improving the part's final look, feel, and performance.

Its main goals are:

A layer of pigmented liquid (paint) is applied and then cured (dried).

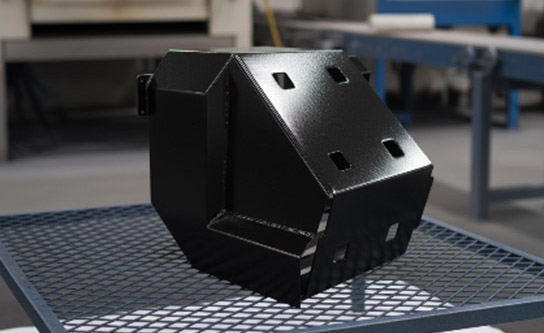

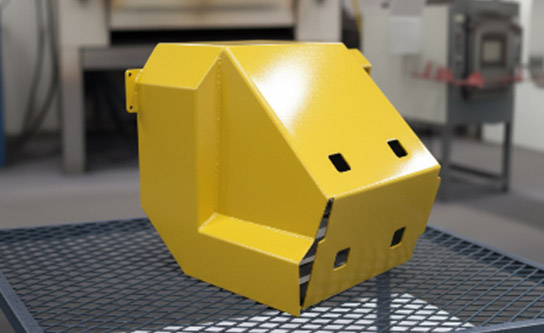

A dry, powdered polymer is electrostatically applied to a grounded part. The part is then heated, causing the powder to melt and fuse into a smooth, durable layer.

A thin layer of metal is deposited onto a conductive surface using an electric current (electroplating) or a chemical reaction (electroless plating).

Color Effect: The color is that of the plated metal.

Purpose: To add a thin layer of metal to an object for corrosion protection, increased durability, electrical conductivity, or for a decorative metallic finish.

Appearance: A uniform, smooth metallic surface. The final look is that of the plated metal, such as bright and shiny chrome, dull zinc, or lustrous yellow gold.

An electrochemical process that grows a hard, durable layer of aluminum oxide on the surface. This oxide layer is naturally porous.

A chemical conversion coating for ferrous materials (steel and iron). The process creates a layer of magnetite () on the surface.

A chemical coating applied to aluminum, zinc, and cadmium.

Surtec 650 is a brand name for a chromate-free conversion coating. It's a chemical process where a metal part, usually aluminum, is dipped into or sprayed with a solution containing trivalent chromium. This creates a thin, inorganic passivation layer on the surface.

Also known as electrocoating, this process is like a combination of plating and painting. The metal part is immersed in a water-based paint bath (which can be epoxy, acrylic, or other resins). An electric current is applied, causing the paint particles to deposit onto the part's surface. The part is then removed and baked in an oven to cure the coating.

Coarse processes that use abrasives to remove significant material and shape a part.

A finer abrasive process that removes microscopic scratches to create a smooth, reflective surface.

Parts are placed in a tumbler with abrasive media. The vibration or rotation causes the media to rub against the parts, removing burrs and smoothing surfaces.

High-velocity particles (like steel shot, glass beads, or sand) are blasted against a surface. This is often used to strengthen the material or create a rough, uniform texture.

This is a robust corrosion protection process, primarily for steel and iron. The metal part is completely submerged in a bath of molten zinc at a temperature of around 450°C (842°F). The iron metallurgically reacts with the zinc to form a thick, durable, and abrasion-resistant coating that is bonded to the base metal.