Home Industrial Equipments

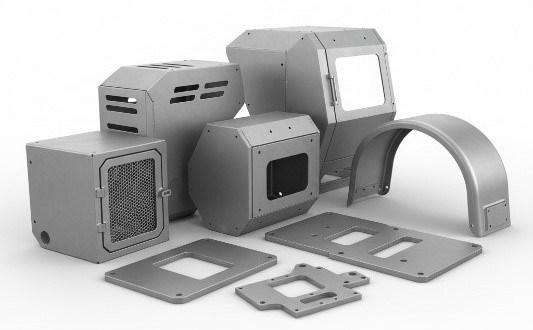

Sheet metal is fundamental to the Industrial Equipment Sector, where it provides the necessary durability, protection, and structural integrity for machinery operating in demanding environments. Its primary function is in creating the external casing and protective systems for various industrial machines. Specifically, this involves the manufacture of heavy-duty sheet metal guards and machine enclosures which are essential for protecting internal mechanical and electrical components from dust, debris, and potential impact, while also ensuring operator safety by covering moving parts.

Manufacturing robust and reliable components, particularly for protection and housing.

Creation of heavy-duty sheet metal guards to cover dangerous moving parts.

Fabrication of machine enclosures and cabinets to protect sensitive internal components from environmental factors.

Used for control panels, equipment housings, ductwork, and conveyor frames.

Sheet metal forming for large casings, complemented by precision CNC machining for high-tolerance shafts and fittings.

Often uses thicker gauge steel for durability and resistance to impact and vibration.

In this sector, the applications combine large formed sheet metal structures with high-precision components. Sheet metal forms the larger fabricated parts like cabinets, housings, control panels, and conveyor system components. However, for critical moving or connecting elements, CNC machining is used alongside sheet metal fabrication to produce accurate, high-tolerance components such as shafts and fittings. This dual approach ensures that industrial equipment is built with robust external protection (sheet metal) and highly reliable, precisely manufactured internal mechanisms (CNC machined parts), delivering the required robustness and reliability to Original Equipment Manufacturers (OEMs).